"A submersible pump with all its components--the motor and hydraulics--must work efficiently in order to achieve the greatest overall efficiency and the lowest energy consumption," explains Martin Senkowski, Head of Design and Development at HOMA. Therefore the company, which has its core competence, is in the field, created initially a new concept for the engines, which can now be set up either wet or dry. This is made possible by the PermaCool system, a new, permanent motor cooling. In addition, the new motor generation allows responding more specifically to special requests from customers: Among other things, during the designing of the units, great importance was placed on the fact that all standard monitoring devices are feasible even for small engines.

At the same time, the new design ensures that the cooling jacket cannot clog with solids matters, resulting in a high operational reliability is achieved. This is further supported by the mechanically robust construction and the low winding temperature, which leads to lower thermal stresses and hence to a longer service life. The efficiency of the engines could be improved significantly; the models of the EffTec Series are therefore in compliance with the Premium Efficiency IE 3 class.

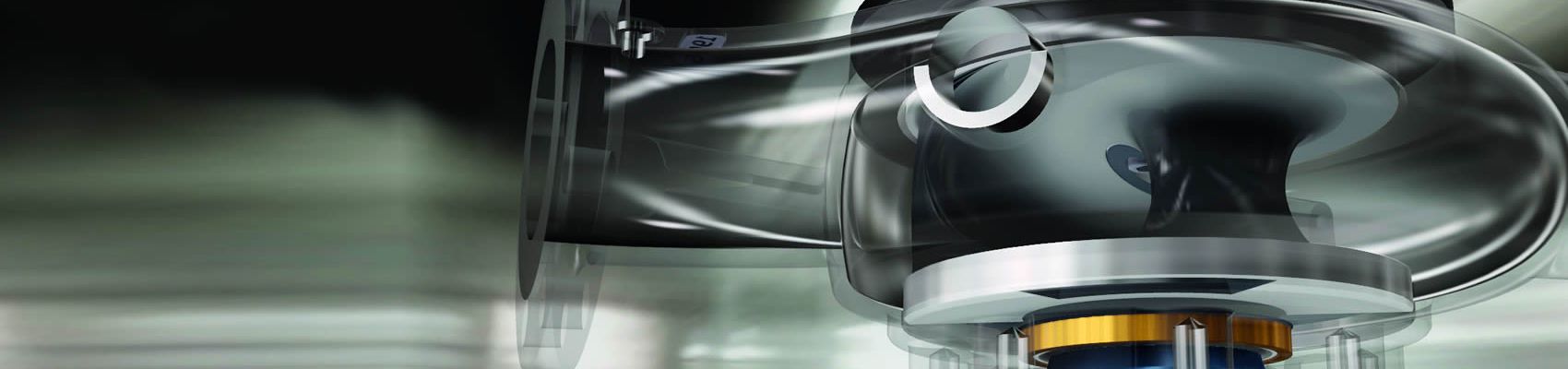

To achieve a high overall efficiency, the hydraulics has been changed in conjunction with the motor: In particular, the essential components of any centrifugal pump, the impeller and the pump housing have been completely redesigned. "The nature of the wastewater has changed significantly in recent years; it always contains more solids and less water. Therefore, a pump is needed that works reliably under such conditions," explains Senkowski. Therefore, the new series uses only closed single channel impellers with large ball passages, i.e. a large free passage for solids. To achieve the technically difficult optimization of these components, HOMA fell back on its decades of experience and combined them with modern flow simulation software. In this way, it was able to significantly improve the efficiency of the single channel impellers, while providing a low risk of clogging. In addition, the hydraulics were mechanically revised, allowing the EffTec Series to have a very high running smoothness, which minimizes the stress on all components. The new EffTec-Series can be ordered here.