Counteract increasing failures due to tressing

Waste water with increased fibre and solids content

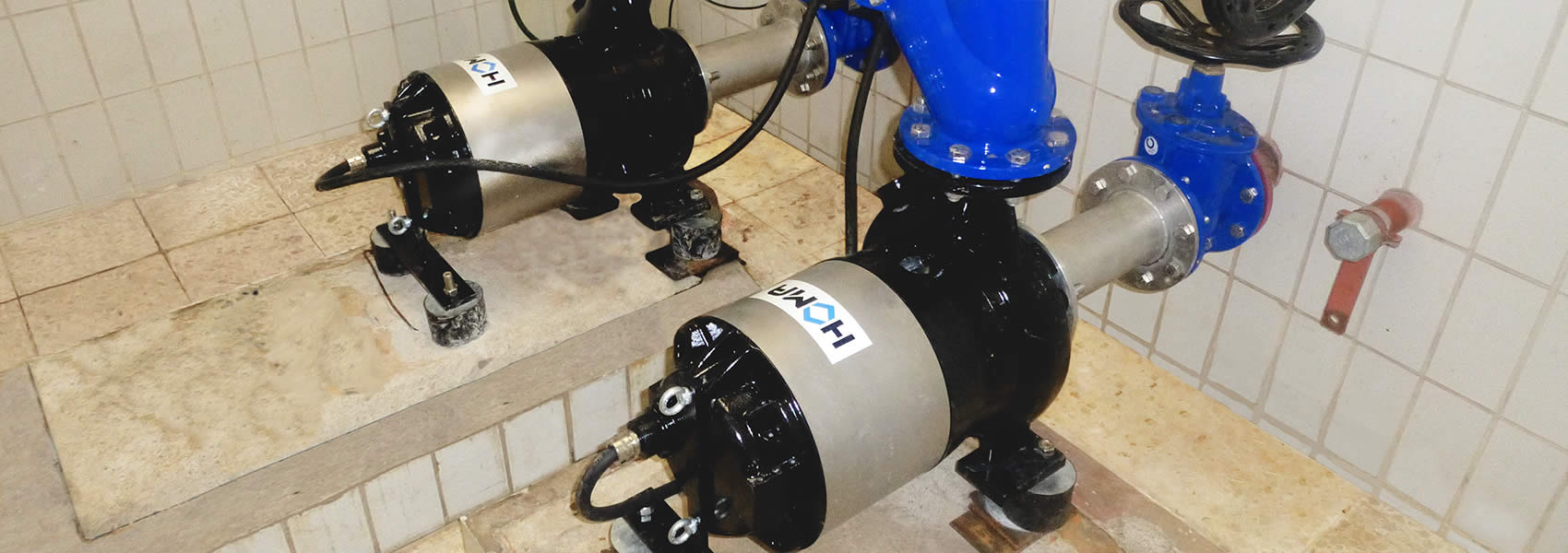

Two pumps of the EffTec series

Industrial and waste water technology

Up to the end of 2014 in a pumping station in Grassau, Upper Bavaria, pumps made in the 1980s were still in operation, and were replaced at the beginning of 2015. The newly-installed pumps with optimised motors and hydraulics are now ensuring high effectiveness in accordance with Premium Efficiency IE 3. In order to move the effluent more efficiently in future, and to counteract the increasing problems of blockages, the local council decided to replace the old models with new pumps from HOMA's EffTec range. These are especially suitable for difficult operating conditions - such as a significant content of solids - and have now been employed for the first time in Grassau with dry-well installation. Thanks to the newly-designed motor and the mechanically optimised hydraulics, these single-channel impeller pumps have not only proven themselves through their high efficiency, but also through their exceptionally smooth operation, which considerably increases the operating life of this sturdy design. The units pump 13 l/s and have been operating trouble-free since January 2015.

"The pumps which we were using until 2014 at the pumping station in Erlenweg were already about 30 years old, and were no longer particularly efficient compared with modern pump types", says Sebastian Stephan from the Grassau Waterworks. "In order to get up to the latest state of the art in pumping technology and to be able to dispose of the waste water as well as possible during the next few years, the local council decided to update the pumping station." Since this market town was already successfully using a number of HOMA pumps for this purpose, the people in charge decided for this reason to purchase models from the manufacturer near Cologne. Since before the pumps were replaced, the old units were suffering from a noticeable increase in problems with blockages/entanglements, the initial choice was for vortex impeller pumps, which have a reputation of being particularly unaffected by these problems.

However, after installation of the new models, there was a repeat of the difficulties with blockages. "In our opinion, this was due to the high concentration of solids and the relatively low flow speeds inside the pump.", explains Markus Steimel, Service Manager and managing this project at HOMA. In general, employees of the pump manufacturer have recently noticed an increase in problems due to clogging in pumps, which can be attributed to the ever-reducing portions of extraneous water in the sewers and an increase in non-degradable solids - especially wet wipes. "Particularly with vortex impeller pumps, the low flow velocity combines with the centrifugal effect to promote a separation of the denser water from the less dense solids. That can easily lead to blockages and clogging.", says Steimel.

Since the maximum performance of the pumps in Grassau is limited by the available power supply, it was not possible to gain any positive change using the existing models or the existing impeller variants. Therefore, HOMA recommended the use of pumps from the EffTec range.

"We already used this newly-developed type of pump in various pumping stations before the Grassau project, where there was a considerable load of solids, and in these applications we obtained proof of its reliability, particularly under difficult operating conditions.", explains Steimel. However, since those have been exclusively pumping stations using wet installation, the manufacturer wanted to test the application in Grassau using units in a pumping station with a horizontal dry well installation. "The fact that the EffTec models can be installed either "wet" or "dry" is down to the patented PermaCool System, an innovative, permanent cooling system for the motor.", says the expert.

For this series, the whole of the motor was newly designed. Hence, for example, the special design ensures that the cooling jacket cannot get covered with solids, which provides a high degree of operating reliability. This is supported by a very robust mechanical design and a low winding temperature, which leads to lower thermal loading and an increase in operating life. Through the considerably improved efficiency of the motors, the EffTec models achieve a Premium Efficiency Classification of IE3.

In order to achieve a high degree of efficiency, the hydraulics were modified, as well as the motors: in particular the key components of every centrifugal pump, the impeller and the pump housing, were entirely redesigned. In order to operate reliably in the presence of the changing quality of the waste water with an increasing amount of solids, the new series only uses closed single-channels with large ball passages, i.e. large free passages for the solids: "By using flow simulations, we created an impeller that generates almost ideal flow conditions without disruptive eddies. This means that fibrous materials are moved optimally through the pump hydraulics, and the danger of clogging is reduced to a minimum.", explains Steimel. In addition, the hydraulics were mechanically redesigned so that the EffTec series operates very smoothly, reducing the loading on all components. .

"Since the single-channel impeller pumps were installed in Erlenweg in January, there have been no further problems with blockages.", says Stephan. In addition to getting a trouble-free pumping station, the dismantling and reinstallation of the units was very important for Markt Grassau since the entire waste water disposal for the district of Mietenkam flows via this pumping station. After its replacement, the operating point of the station is now at h max = 10 m and the pumping volume is 13 l/s. "These values are very different from the ones for the 1980s pumps, and for example, the switching points of the old models were much slower.", explains Stefan. "And after replacement, electricity consumption has also reduced considerably."