70 years of experience in pump manufacturing. The secret of success of HOMA Pumpenfabrik GmbH started over 75 years ago: In 1946, Hans Hoffmann first set up a local trade company for repairing electric motors. From there, an industrial company working globally that has become part of the German ‘Mittelstand’ has developed.

HOMA is still family-owned and is now managed by Hans Hoffmann in the third generation.

From the production site and headquarters in Neukirchen-Seelschied near Cologne, HOMA pumps are sold from around 100 branches and dealerships worldwide.

Senior Manager Hans Hoffmann passed the master craftsman's diploma as an electrical engineer. He decided to go independent immediately and, in a small former stable building, he opened a repair workshop for electric motors in the district of Kotthausen. Two years later, he set up a residential building in 1948, on the ground floor of which were spacious offices and workshop rooms. Quality Spreads. Rapidly, well-known companies from the region became customers, but the staff numbers are still manageable. In the family business, Wally Hoffmann, the wife of the senior boss, cooked lunch for the staff and everyone ate together in the spacious residential kitchen.

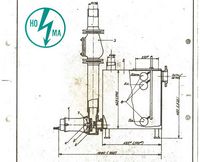

Hans Hoffmann took the decision that characterises the business to this day: specialisation in the development and manufacture of submersible motor pumps. They had already outgrown the premises. For a short time, the family garden of the Hoffmanns had to be converted into a production hall. Lathes and drills machined the pump parts, electric motors were wound and finally assembled into finished pumps. The manufacture of powerful effluent pumps and construction & manure pumps for agriculture developed into the core competence of the company. The company name HOMA Pumpenfabrik was formed by combining the family name HOffmann with the German term for mechanical engineering.

At the beginning of the sixties, HOMA intensively worked mainly in sales activities on an international level. Many of the sales partners in export from that time are still loyal customers today. Primarily in Europe, more and more customers were delighted by the HOMA quality. We also began to develop a new series of products, especially for conveying sewage in the communal and industrial areas. It is just this area that grew rapidly over the next few years, and to date forms HOMA's main area of business.

HOMA starts to design and manufacture submersible motor pumps for construction and therefore exploits a completely new market. Already part of the HOMA product range at that time were: a small submersible pump with float technology the “Niveaumatik” for automatic level regulation.

At the end of the 60s, HOMA had a new product in the range: lifting systems. Then, as now, the systems are suitable for sewage and faecal matter. With a manual pump, the system can then by pumped empty by hand.

The residential building in Weesbach was no longer suitable for the production requirements. The company moved to its site in the Oberheister industrial estate. The HOMA name proudly hangs in red letters above the new production hall. The family settled in the home nearby. At the same year, Hans Hoffmann founded the company “HOMA Exports Ltd.” and “Irish Blackwater Castings Ltd.”, which cast aluminium parts in the Irish town of Mallow for the production in Oberheister. In the Netherlands, for sales and servicing there, “HOMA Pompen B.V.” was set up and for the French business “HOMA France s.a.r.l.” in Paris.

In the 1980s, HOMA expanded over the pond, and in 1981 started selling through a cooperative partner in the USA. From the site in Ansonia, Connecticut, HOMA pumps are sold throughout the United States.

HOMA expanded. In 1982, a second production hall with a new administrative building and a new warehouse were set up on the Neunkirchen-Seelscheid site. The products are becoming more and more varied and the first model of the GRP grinder pump Barracuda appeared on the market. The robust grinder ground down the solids carried in the medium effectively, before carrying them away, thus preventing the pumps from becoming clogged or blocked. Even today it is one of the flagship products of our company.

After the German reunification (1989/90), Hans Hoffmann and HOMA Pumpenfabrik GmbH also committed to former eastern regions, as they bought the “trusteeship” of the companies “Elekroinstallation Wittenberg” and “Leuchtenbau Wittenberg” and incorporated them into the group of companies. Hans Hoffmann was particularly in touch with nature. So, he was particularly proud of acquiring the second largest forestry operations in East Germany. In the forest operations Zehrendorf and Merzdorf (with an area of over 1 000 ha.), the monocultures were converted to mixed forests, in which thousands of beech trees and red oaks were planted.

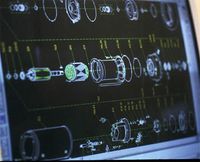

The pumps required on the market were getting increasingly large, and from the mid-90s, the first large pumps up to 630 KW left our factory in Neunkirchen-Seelscheid for their use in sewage treatment across the world. HOMA also worked hard to expand. At the site in Oberheister, a third production hall was put up as well as another administrative building. Also digitalisation started to take shape at HOMA.

HOMA conquered new markets and gained new cooperative partners. Meanwhile, in over 60 countries, there are established sales partners for our pumps. Particularly important in the internationalisation are specialist trade fairs such as here in Singapore.

HOMA is continuing to grow. In 2000, a fully-automatic high-shelf warehouse was set up with approx. 3500 storage locations, to guarantee the availability of spare parts. In the same building is located a new test setup as part of quality control. The product range was constantly extended and adapted to the needs of the market. HOMA absorbed mixer and injector technology for various applications of homogenisation, suspension, generation of horizontal flow and rinsing away of deposits in liquids into the supply range. Internationally, the HOMA brand is more and more sought after. The quality pumps that are made in Germany are used across the world and are now turning in over 60 different countries.

Hans Hoffmann died suddenly and unexpectedly on 14 January 2012. Hans Hoffmann's life's work stood as an example of an economically successful and also socially aware & responsible way of doing business. It has always been open to the problems and questions of its staff.

HOMA's investment in the future has already begun. To be able to continue to have sufficient capacities at its disposal, HOMA has invested € 3.5 million in a new company building at the headquarters in Seelscheid. As well as expanding production, the building also includes a modern training centre – the HOMA Academy. A test pool with online test rig for pumps of up to DN 1000 and for mixers and flow accelerators has been integrated.

The EffTec series combines several innovations into one series at the same time: maximum efficiency through optimised motors, non-clogging MXS hydraulic systems and the integrated PermaCool cooling system for a longer product life cycle.

A new superhero and all-round performer extends our product range. The Bully C140, a new generation of pumps with lever float, the stainless steel shaft of which, with ceramic coated sealing face, allows continuous operation. This new model is the first pump from HOMA fitted with a lever float. Our know-how from over 70 years of experience in the development of effluent and sewage pumps has particularly flowed into the design of this component, as well as all the others, of course. In the meantime, the blue and also the red Bully CH140 work together for conveying chemically-corrosive media.

HOMA revolutionises the use of propeller pumps to protect against flood water. The newly-developed, patent-protected HOMA infeed chamber optimises the water supply and flow of the propeller pump hydraulic system. There is therefore no need for an expensive construction design with concrete sections. Retrofitting to HOMA units is possible without any problem, regardless of the structural conditions.

The largest building project in the history of the company is entering its second round. After the second building stage concluded in 2013, the starting shot came in 2017 for the much larger construction of a production hall on the Neunkirchen-Seelschied site; HOMA is ready for the future. In over 100 countries, the demand for pumps, lifting systems and services from the Hoffmann family business is increasing. By constructing the new hall, we can serve the increased demand and have set the bar for a successful future.

From the coarse scraper to the filigree noble technician: With the new Chromatic® series, no less than 11 special pumps expanded our product range and since then have been keeping dirty water at bay in every position. Whether as a robust dirty water pump, for chemically contaminated media, as a flat suction pump, with sensor switch or integrated float switch for narrow shafts. During development, it was important to design a professional pump for every application. In addition, the uniform and functional design played an important role.

6.562,5 m²! That's about the size of a Bundesliga football field and that's how large the area is that we are gaining with our new hall. A total of 58 employees and 43 large machines weighing up to 24 tonnes have found a new place here. The engine winding department is located in the basement and can now work perfectly with the mechanical processing department on the upper floor. In addition, the processes are facilitated because material is taken from more than 1,600 storage places and used for production. With our new hall, we have clearly structured the material flows on two levels and thus achieved much higher productivity and significantly shortened delivery times. This major project means that we can easily meet the growing demands of the market and have set the course for a successful future.